Shipping Container Parts

Shipping Container Parts in Stock and ready for fast shipping right to your door. Ultimate Bunker is Located in Salt Lake City, Utah. 801-661-3900

We have in stock over 3500 repair parts for ISO shipping containers. Our large inventory of ISO Shipping Container Parts are 100 % OEM parts made from High Quality CORTEN Steel.

Do you need your shipping container Modified? Our fabrication team can help!

Ultimate Bunker is a full-service manufacture offering repairs as well as, New Custom Built Shipping Containers.

Ultimate Bunker has shipping container parts in stock and ready to ship!

Give Us a Call Now! 801-661-3900

Shipping Container Parts in Stock

All our Steel Container Parts are Made of High Quality CORTEN Steel

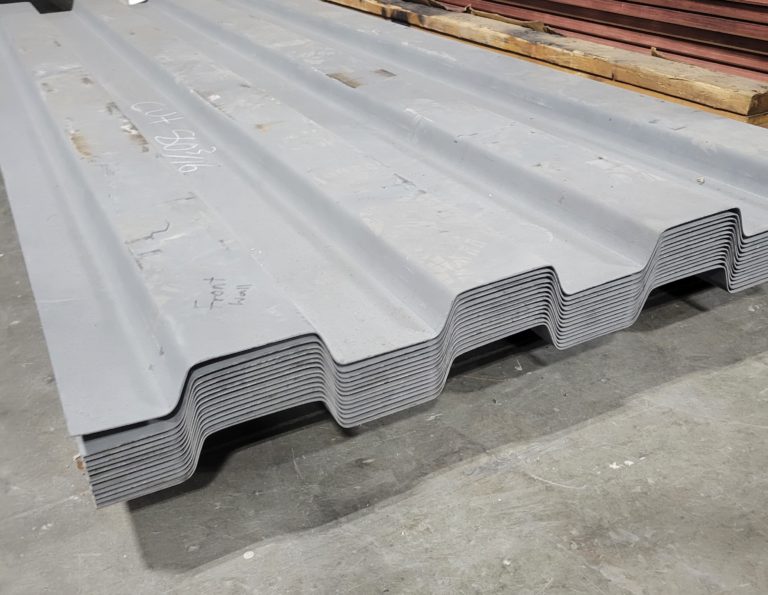

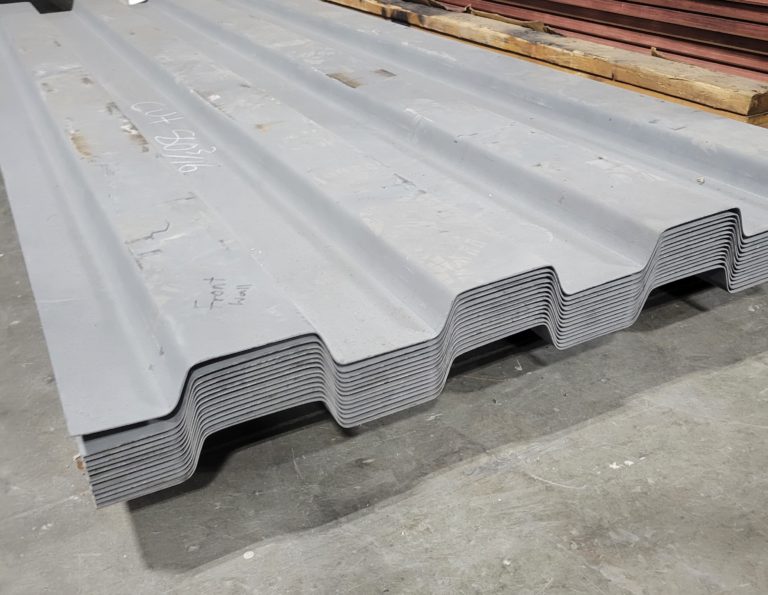

- Side Panels

- Roof Panels

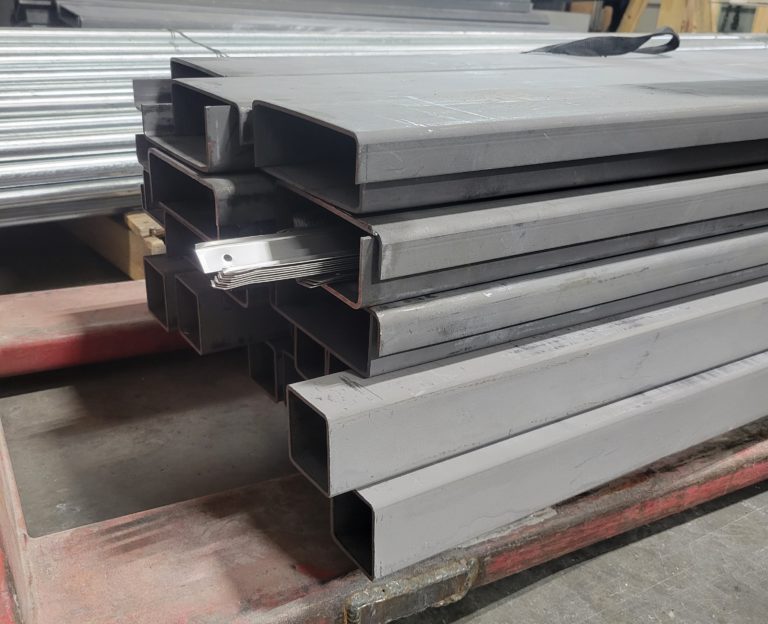

- Crossmembers

- Corner Post

- Doors and Door Hardware

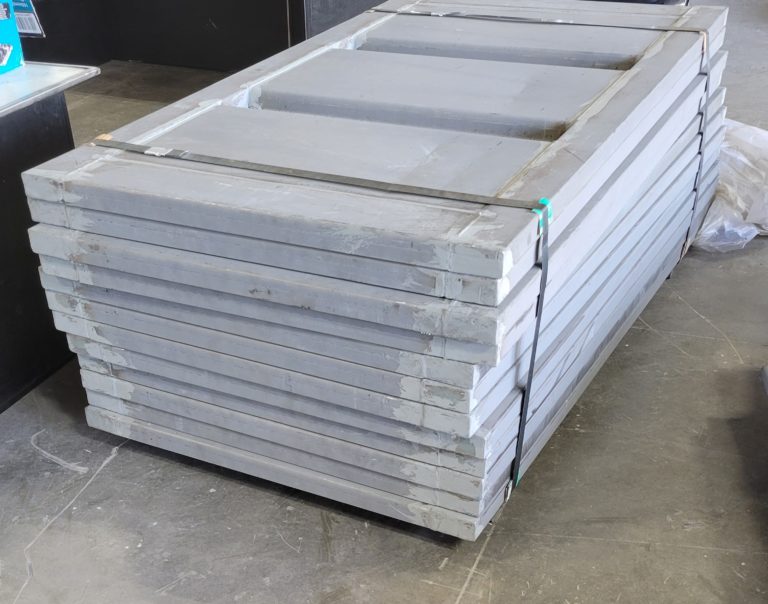

- 1 1/8 Marine Grade Shipping Container Plywood

- Lock Boxes

- Hinges and Pins

- Lashing Rings

- Corner Castings

- Bottom Side Rails

- Top Side Rails

- Nuts and Bolts

- Door Gaskets

- Lock Rod Kits

- Vents

- Front End Panels

- Fork Lift Tunnels

- Paint and Sealants

- Design and Consulting Services

- Casters and More

Do You Need Custom Shipping Container Parts? We Have Them in Stock. Give Us a Call Now! 801-661-3900

Is an ISO container the same as a Conex?

Shipping Container or Conex Box: Is There really a Difference?

Whether you call them “shipping containers,” “storage containers,” “Conex” (or Connex) boxes,” or “ISO boxes,” they are all the same thing – large metal, weather-resistant containers used to store or ship things.

What type of plywood is used in shipping containers?

Shipping container flooring is made of 1 and 1/8th inch thick marine grade plywood. Marine plywood was created in the 1930s and used to build ships during World War two. Marine-grade plywood is sturdier, higher-quality plywood. It’s manufactured with fewer defects than standard plywood, so it’s longer-lasting.

What is CORTEN Steel?

What kind of steel is used in shipping containers?

The corrugated wall panels, frame, cargo doors, and cross members of metal shipping containers are all made from CORTEN steel. This special type of steel, also known as weathering steel, is the primary material in shipping containers.

Why is CORTEN steel used in shipping containers?

Often built to transport cargo around the world, they are transported by boat and are exposed to all outside elements. Because of this, manufacturers use CORTEN steel so the units have an additional layer of protection to prevent them corroding.

What is special about CORTEN steel?

Using Corten Steel in Planter Design & When specifying …

Corten Steel is also known as a ‘weathering steel’, as the steel forms a protective layer on its surface under the influence of the weather; and it is this protective layer that gives Corten far superior resistance to atmospheric corrosion, compared to other steels.

Is CORTEN Self Healing?

The layer protecting the surface develops and regenerates continuously when subjected to the influence of the weather. The same process allows Corten to ‘heal itself’. So, if, say, the surface is scratched, then the exposed area will regenerate its protective layer; and, over time, this area will blend in with surrounding areas, and be essentially invisible.

Counter-intuitively, Corten Steel doesn’t actually like being constantly dry; and nor does it like being constantly wet. In fact, what Corten Steel likes best of all is to be wet, then dry, then wet, then dry – and so on. In other words, the degree to which Corten’s surface weathers [and thus its ultimate longevity] is positively improved by being subjected to repeat wet-dry cycles.

CORTEN Steel is also known as Weathering steel

often referred to by the genericised trademark COR-TEN steel and sometimes written without the hyphen as corten steel, is a group of steel alloys which were developed to eliminate the need for painting, and form a stable rust-like appearance after several years’ exposure to weather.